Yielding-overcoming training device (UPTU) is intended for speed-strength training of track and field athletes, mainly throwers and jumpers. In addition to training track and field athletes, athletes of other speed-strength and power-oriented sports can successfully train on this simulator.

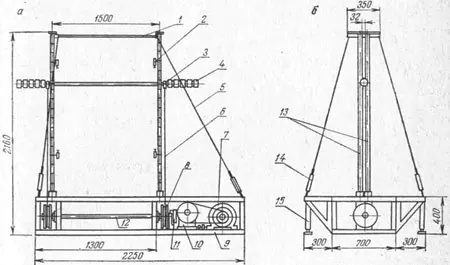

The device (see figure) consists of a welded frame 9.15 measuring 1300X2250X430 mm, which also serves as a platform. The upper part of the frame is covered with boards and mats, forming a platform.

Four vertical tubular posts 13, paired with each other, are inserted into glasses that are welded to the frame. At the top, the racks are secured using a rod 1 and four cables 5, connected by tension bolts 14. The distance between the racks is 1085 and 35 mm, the height of the racks is 2160 mm.

Between the racks there is a barbell 4, on which special locks 3 are put on, connected to a cable 6. In addition, electric limit switches (KB) 2 are attached to the racks. When the barbell is raised to the upper position, they turn on the electric coupling 11, which firmly connects gearbox 10 to pulley 8, and when the bar is lowered it is turned off. The limit switches can be adjusted to any height as desired, since the posts have holes every 50 mm.

Installed inside a welded frame DC motor 7 with a power of 1.5 kW. The motor shaft is connected to the gearbox via a belt drive. In this case, the distance between the electric motor and the gearbox can be changed arbitrarily and thereby maintain the required tension of the belt drive.

The gearbox is connected in series to an electric coupling, which is inserted into a special cartridge and mounted on shaft 12. Two pulleys for winding the cable are also mounted on a shaft mounted on ball bearings and specially attached to the frame. The shaft with the pulley plays the role of an external burden for the athlete when working in the overcoming mode of muscle activity. The resistance value of the rotating shaft with pulleys is 40 kg.

Speed strength training for track and field athletes on the UPTU simulator involves lightning-fast changing the inferior mode of muscle work to the overcoming one, which happens very abruptly and resembles a breakdown. At the top, the barbell again touches the upper KBs, which turn on the electric clutch, and the whole job starts all over again.

The device also has remote wireless switch electrical circuit, which must be kept by the trainer during operation in order to timely turn off the entire electrical part of the installation.

The starting part of the device consists of a relay, a starting rheostat, a rectifier and a rheostat for adjusting the engine speed. To activate the clutch, a transformer, a bridge of four diodes and a contact brush are used, through which electric current is supplied to the slip ring of the clutch with a voltage of 24 V. Before starting work, you need to use the starting rheostat to adjust the speed of the electric motor, and, consequently, the speed of lowering the bar rods from the top to the bottom position.

Post Views: 108