More recently, our attention was drawn to an incredible fact that few people knew about until now. It turns out that even before the appearance and widespread development of bodybuilding in our country, at a time when weightlifting “ruled the show,” our fellow countryman, an outstanding designer P.E. Petrov a sports training device was assembled exactly similar in its functional qualities and purpose, widely known to all bodybuilders "Smith's machine" (see picture No. 3)…

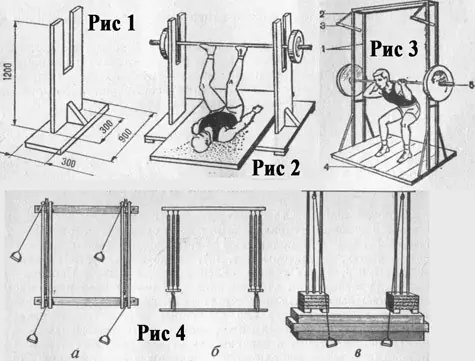

The basis of any weightlifting machine is the platform and racks (see Figure No. 1), installed on both sides of it. Movable or fixed devices (hooks, clamps, etc.) are made on the racks, on which the barbell is mounted. There can be several such devices at different levels, with a bar of different weights being raised to different heights. Additional horizontal or inclined planes are also installed on the weightlifting platform. An ordinary bench can be used as a horizontal plane. Lifting the barbell, depending on the tasks assigned to the practitioner, is performed in various positions: standing, sitting, lying down, actively using the muscles of the arms or legs (see Figure No. 2).

Schematic figure No. 3 shows a simple weightlifting machine for performing strength exercises, proposed by P. E. Petrov. It consists of four vertical metal fretboard posts welded to the base. The distance between the racks in width is 40 mm, in length - 1180 mm. The main unit of the simulator, which allows you to combine muscle work modes, is the clamps to which rubber shock absorbers are attached. The clamps are mounted on a stand that has holes every 100 mm for moving them up or down.

When lifting the barbell, the bar presses on one of the arms of the clamp, and a rubber shock absorber is attached to the other arm. Thus, the tensile force of the shock absorbers is added to the weight of the bar. By changing the ratio of the clamp arms, you can change the amount of additional force within a wide range.

1 - racks; 2 — shock absorbers; 3 — clamps; 4 — weightlifting platform; 5 - barbell, discs and locks

Guide frames, durable amplitude limiters and spring locks (or screw-type locks) - all these elements are designed to maximize secure work weightlifter or bodybuilder on this machine.

A significant effect in the development of strength, speed-strength and other qualities of weightlifters can also be achieved with the help of so-called strength, muscular and weight-lifting training devices widely used in bodybuilding and fitness. The basis of their design is a set of power elements: springs, expanders, weights with reliable locks (see Figure No. 4)

Types of strength training equipment:

- a) a simulator for creating tensile forces;

- b) a simulator for developing arm strength;

- c) block kettlebell trainer

How is a platform for training with a barbell made?

Design is a 3x3 m shield, 80 cm thick, assembled from 12 wooden rectangular sections connected by transverse ties made of steel pipes. Each section is assembled using casein or resin glue, from birch or pine boards, with a cross-section of 40-60 x 100 mm and a length of at least 1 m. The dowels are made of oak wood.

The boards are tightly jointed to each other. When gluing in adjacent layers of wood, the sapwood should face the sapwood, and the heartwood should face the heartwood. The distance between joints along the length is at least 0.5 m. The assembled section is carefully planed. The outer edges of the side sections are rounded, and triangular grooves for the keys are selected on the lateral contacting planes. Each section is painted with stain, and then covered on all sides twice with a hot solution of drying oil and rosin.

Screeds are made from water pipes. The axes of the holes for the ties and the axes of the grooves of the keys are located parallel to the working surface of the structure. Bougies and sockets are tightly inserted into the ends of the pipes and reinforced with rivets. The rivet heads are filed flush with the surface of the pipe. Metal plates are placed under the bolt heads, fastened with screws flush with the end surface of the structure. All metal parts (except threads) are painted with oil paint or asphalt varnish.

Post Views: 126